Phoenix Beverages, Mauritius, Automates Quality Control with Skalar SP2000

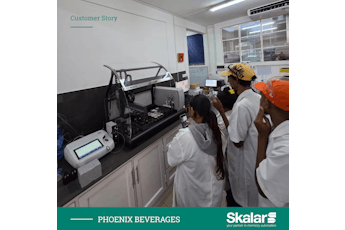

Skalar is proud to announce the successful installation of the SP2000 Robotic Analyzer at Phoenix Beverages in Mauritius. This marks an important step forward in automating their quality control processes, particularly in the analysis of bitterness, which has traditionally been a time-consuming manual task.

The journey to this achievement began with initial meetings in Mauritius, followed by several visits, online discussions, and valuable references from industry peers. After more than two years of collaboration, the project has now come to fruition.

Customer feedback

Sophia Henriot, Process & Quality Control Manager at Phoenix Beverages, shared her experience:

“The SP2000 is finally up and running! The training and commissioning went really well, thanks to Rudie, who was of great help throughout the process.

Automation of bitterness analysis will help us streamline our workflow, ensure consistency, reduce human error, and free up our lab personnel to focus on data interpretation and continuous improvement.

After more than three decades of manual analysis, we’re proud to lead the way in introducing this technology to the Indian Ocean region.”

A step towards innovation

With the SP2000 now integrated into their laboratory, Phoenix Beverages strengthens its Quality Assurance process, increases testing frequency, and embraces a more proactive approach to production monitoring.

We thank Sophia Henriot and the Phoenix team for their trust in Skalar, and we look forward to supporting their continued success.

To learn more about the SP2000 Robotic Analyzer