Tobacco analysis

To be able to maintain the high industry standards, Skalar’s analyzers are able to test the raw tobacco materials to insure the quality of the finished product.

QUALITY ASSURED

The well proven Skalar automated tobacco analyzer has been in use for many years in the tobacco industry, and is designed to comply with standard methodologies such as Coresta and ISO. The automated analysis achieves better response times, less operator intervention and an increased accuracy in the results

ACCURATE RESULTS

The ability of the analyzers to give accurate results time after time is what most laboratories regard as the deciding factor before purchasing a system. Skalar has worked with several tobacco laboratories to achieve proven, rapid, accurate and reliable results. The well proven automated analytical methods are based on international standards as specified by International Standard Organisation (ISO), Coresta, etc

TIME EFFICIENT

All Skalar analyzers not only automate routine methods, but wherever possible the actual analysis time involved is reduced. This enables operators to increase throughput and thus increase the overall capacity of the laboratory. Short response times to detect changes in production are important for a better control of the process

COST EFFECTIVE

The tobacco analyzers have proven to be robust workhorses for tobacco laboratories. The low operational costs simplify the choice to automate applications, bearing in mind an increase in speed and reliability. In addition, less waste per sample analyses is produced compared to the traditional manual method.

Our automated solutions for the tobacco industry

The SAN++® Series continuous flow analyzer has been in use for many years in the tobacco industry and is designed to comply with standard methodologies as Coresta and ISO.

Features

- Unattended automatic start-up and shutdown

- Automatic preparation of calibration standards

- Minimal operator contact with dangerous chemicals

- In-line dialysis for handling tobacco extracts without filtration

- Various types of autosamplers with 50 up to 576 sample positions

Parameters

- Ammonia

- Nitrate+Nitrite

- Phosphate

- Nicotine/Total Alkaloids

- Chloride

- Cyanide

- Total Reducing Sugars

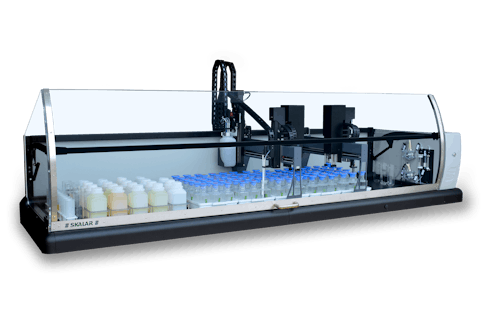

The SP2000 Series robotic handling system offers full automation on the addition of extraction solution, shaking and filtration of tobacco samples. The sample filtrate can be offered in addition to the autosampler of the SAN++® Series CFA analyzer for further analysis. The SP2000 Series automates the sample preparation incl. (de)-capping the flasks, addition of acetic acid, sample mixing, sample filtration, needle rinsing and filter replenishing. The automated extraction and filtration procedure is according to CORESTA method 85.